For international businesses engaging with Chinese suppliers, due diligence often starts with official documents like the Official Enterprise Credit Report (OECR) from China’s National Enterprise Credit Information Publicity System (NECIPS). This report provides vital registration details, shareholder information, administrative penalties, and annual filings. While indispensable, relying solely on paper records is a significant risk. Physical factory verification bridges the gap between documented claims and operational reality, safeguarding your supply chain.

Why Paper Reports Aren’t Enough: The Critical Gaps

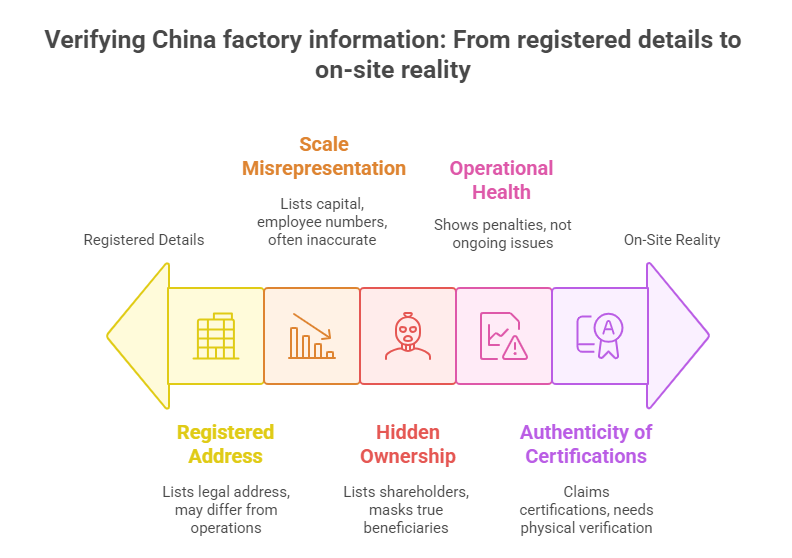

- “Registered” vs. “Operational” Address Discrepancies: The OECR lists the legal registered address. Companies often operate production from a different, sometimes unlisted, location. A report might show a prestigious address in Shenzhen, while the actual factory is in a remote area or even a different province, potentially impacting logistics, oversight, and compliance with environmental/safety standards.

- Scale Misrepresentation: The report lists registered capital and employee numbers from annual reports (often self-reported and optionally hidden, as seen in sample reports where companies frequently “choose not to disclose” financials and headcounts). Actual workshop size, machinery count, production lines, and workforce levels observed on-site can starkly contrast with these figures. A report might suggest significant capacity, but verification could reveal a skeleton crew and idle equipment.

- Hidden Ownership & Affiliate Risks: While the OECR lists shareholders, complex corporate structures or undisclosed related-party transactions (common risks highlighted in our Executive & Shareholder Risk Reports) might mask true beneficiaries or hidden links to problematic entities. On-site visits can uncover clues like shared facilities, management, or branding with unreported affiliates.

- Operational Health & Compliance: The report shows administrative penalties if recorded, but not ongoing issues. On-site inspection reveals real-time operational conditions: safety protocols (or lack thereof), environmental compliance (waste disposal, emissions), working conditions, equipment maintenance, and quality control processes. Are fire exits blocked? Is hazardous waste properly handled? Is quality testing actually happening?

- Authenticity of Certifications: Factories may claim certifications (ISO, BSCI, industry-specific). Verification involves physically checking valid, original certificates on-site and assessing if documented processes are genuinely implemented on the factory floor. Are safety goggles actually worn? Are quality check records filled out consistently and accurately?

Essential On-Site Verification Tactics

A thorough factory visit goes beyond a guided tour. Here’s a tactical approach:

- Pre-Visit Intelligence & Planning:

- Deep Dive into the OECR & Beyond: Analyze the target’s OECR meticulously. Cross-reference with deeper dives like our Professional Business Credit Report for legal risks, financial health indicators (where available), and supply chain insights. Identify red flags (frequent address/management changes, penalties) to investigate. Obtain export licenses, key certifications (copies in advance).

- Define Clear Objectives: What specific risks are you assessing? (Capacity, quality, compliance, labor practices, ownership)? Tailor your inspection checklist.

- Unannounced Element: While scheduling is often necessary, arriving early, requesting an unplanned restroom break, or asking to see a different area spontaneously can reveal unvarnished conditions.

- The Physical Inspection – Seeing is Believing:

- Facility Tour: Go beyond the showroom floor. Demand to see all production areas, warehouses, quality control labs, maintenance shops, waste handling areas, and dormitories (if applicable). Observe workflow, equipment age/condition, material flow, and cleanliness.

- Capacity & Capability Assessment: Count active production lines and machines. Observe worker density per line/shift. Ask for production logs (daily/weekly output). Does the observed capacity match their claims and your order volume needs? Check maintenance records for critical machinery.

- Quality Control Verification: Visit the QC department. Observe testing procedures in real-time (if possible). Review raw material inspection records, in-process checks, and final product test reports. Are they using the required testing equipment correctly and consistently? Talk to QC staff.

- Compliance & Safety Checks: Look for visible safety signage, accessible fire extinguishers/exits, proper chemical storage, PPE usage by workers, ventilation, and ergonomic conditions. Check for evidence of environmental compliance (wastewater treatment, air scrubbers, proper waste segregation). Does it align with their claimed certifications?

- Workforce Observation: Gauge the number of workers relative to the operation size. Observe working conditions, morale, and supervisor interactions. While direct interviews are sensitive, observing breaks or cafeteria areas can offer insights. Verify payroll records against observed headcount if possible/appropriate.

- Documentation & Interview Verification:

- Original Documents: Insist on seeing original, current business licenses, tax certificates, key production/capacity certifications (ISO, etc.), and relevant export permits displayed or provided on-site. Verify names and addresses against the OECR and what you see.

- Management Interviews: Discuss production processes, capacity planning, quality control systems, supply chain management, and compliance programs. Ask specific questions based on OECR findings (e.g., explain a past penalty, clarify a shareholder structure). Gauge knowledge and consistency.

- Financial Health Indicators (Indirect): While full financials are private, observe signs of investment (new equipment), maintenance backlog, or inventory levels (excessive stock or bare shelves).

- Technology & Digital Verification (Complementary):

- Satellite Imagery: Use tools like Google Earth Pro to verify factory location, size, layout, and expansion over time. Compare to the registered address and claimed scale.

- Digital Footprint Check: Review the company’s website, Alibaba presence, and social media. Do posted factory images match reality? Are claimed certifications listed? Is online activity consistent with their business level?

Integrating Verification with Official Documentation

On-site verification doesn’t replace due diligence; it completes it:

- Validating the Official Record: Use the OECR as the baseline truth for legal existence, registration, and recorded penalties. Verification confirms if the operational reality aligns with this legal framework and self-reported data.

- Contextualizing Risks: An administrative penalty on the report might seem minor, but seeing ongoing non-compliance on-site reveals a deeper cultural or management issue. Conversely, verification can provide reassurance that a past issue has been genuinely resolved.

- Informing Negotiation & Contracts: Findings on actual capacity, quality systems, and compliance maturity directly impact pricing negotiations, order volumes, contract terms (e.g., audit rights, quality thresholds), and risk mitigation strategies (e.g., increased inspections, staggered payments).

- Building Trust (or Avoiding Disaster): Seeing operations firsthand builds confidence in a reliable partner. Conversely, discovering significant discrepancies or hidden risks prevents costly investments in a failing or fraudulent supplier.

Conclusion: From Due Diligence to Confident Partnership

The Official Enterprise Credit Report is the essential first step in understanding a Chinese company’s legal standing. However, it’s merely a snapshot of official records. True supply chain resilience requires stepping beyond the paper and onto the factory floor. Rigorous on-site verification provides the critical, real-world context needed to assess operational capability, compliance adherence, and overall reliability.

Combining the authoritative data from official reports with the tangible evidence gathered through physical inspection empowers international buyers to make informed decisions, mitigate unforeseen risks, and build sustainable, trustworthy partnerships with Chinese manufacturers. In the complex landscape of global sourcing, seeing truly is believing – and verifying is essential for success.

ChinaBizInsight

Your strategic bridge to transparent business in China.